Triomatic WP wheel-driven feeding robot

This feeding robot moves around on four wheels, so it does not need a suspension structure. Two independent drive wheels mean that the robot can be easily manoeuvered around the feeding alleys. The wheel-driven feeding robot has two vertical mixing augers, a cross conveyor belt capable of discharging on both left and right, and a volume of 3 m3. A power rail delivers electricity to the robot, but does not impose any stable construction requirements. This continuous power supply ensures that the system will not run out of power. The Triomatic WP 2 300 feeding robot follows the power rail. It can handle a gradient of up to 5% and easily cross thresholds of up to 2". The robot can be combined with all types of Triomatic feed kitchens. In combination with a stationary feed mixer, a feed kitchen for blocks or bales, or storage bunkers for bulk feed, the feeding robot can be used as a fully automated feeding system. A suspended feeding robot is also available.

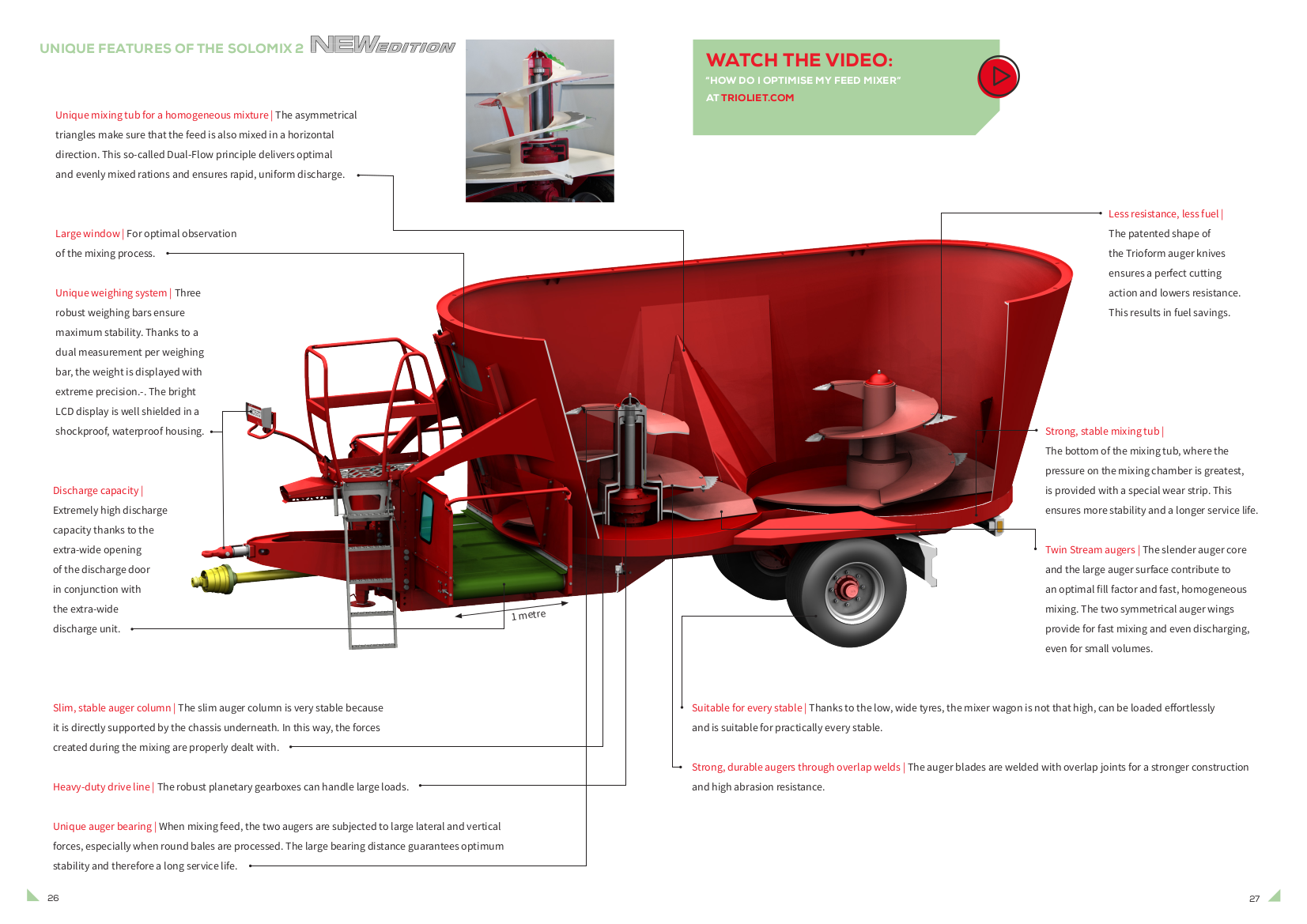

Photos

Standard features

- 110 cu.ft. mixing tub in wear-resistant stainless steel

- Two vertical mixing augers in wear-resistant stainless steel

- Cross conveyor belt capable of discharging on both the left and right

- Touchscreen and operating terminal

- All-electric drive

- Bumper protection

- Continuously variable speed control of the cross conveyor belt and mixing auger

- Four wheels, two of which are powered and two rotating

Technical specifications

| Triomatic | WP 2 300 |

|---|---|

| Capacity cu.ft. | 110 |

| Length | 142" |

| Width | 54" |

| Net weight Lbs. | 4.960 |

| Maximum payload Lbs. | 2.756 |

| Max. offset, left and right from the power rail | 1 |

| Min. (net) feeding alley width | 101" |

| Required connecting current A | 2x32 |

| Required voltage V~ | 400 |

| Max. gradient % | 5 |

| Max. threshold height mm | 2" |